Steel light poles are a popular choice for supporting various outdoor facilities, such as streetlights, traffic signals, and surveillance cameras. They are constructed with high-strength steel and offer great features such as wind and earthquake resistance, making them the go-to solution for outdoor installations. In this article, we will discuss the material, lifespan, shape, and customization options for steel light poles.

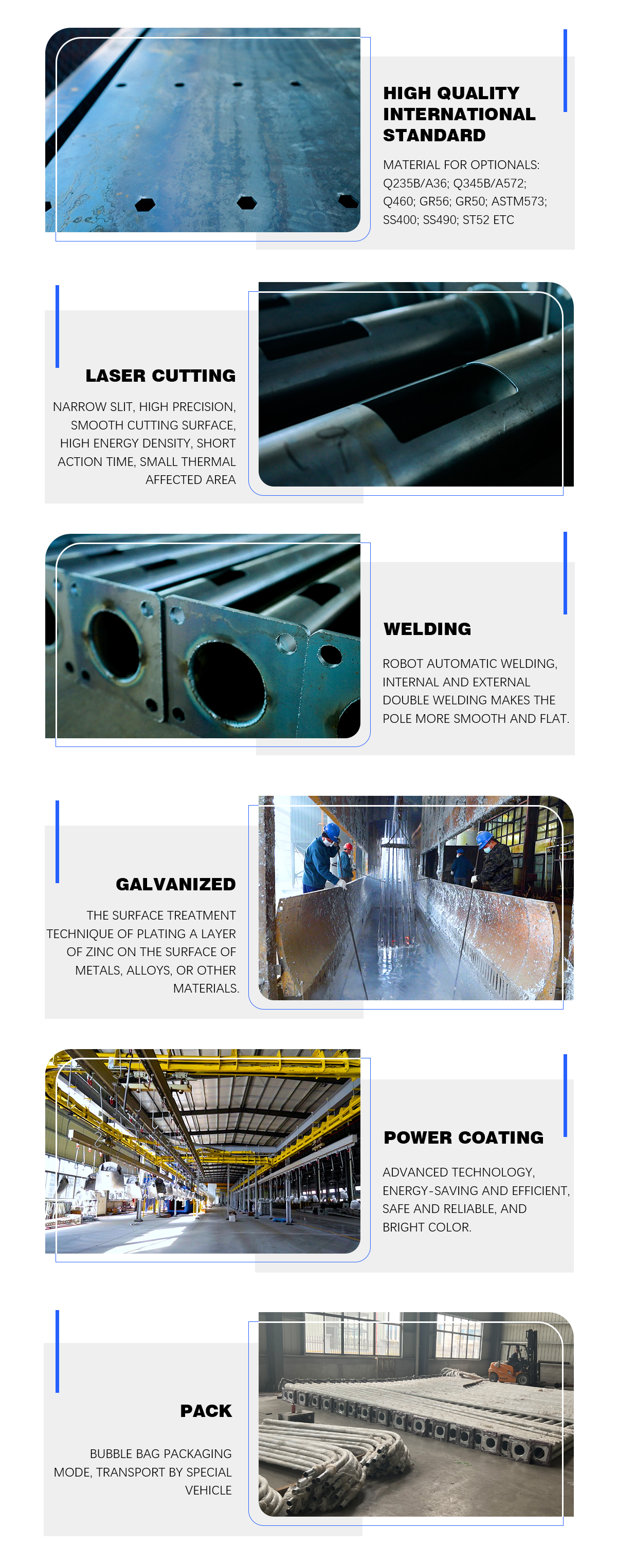

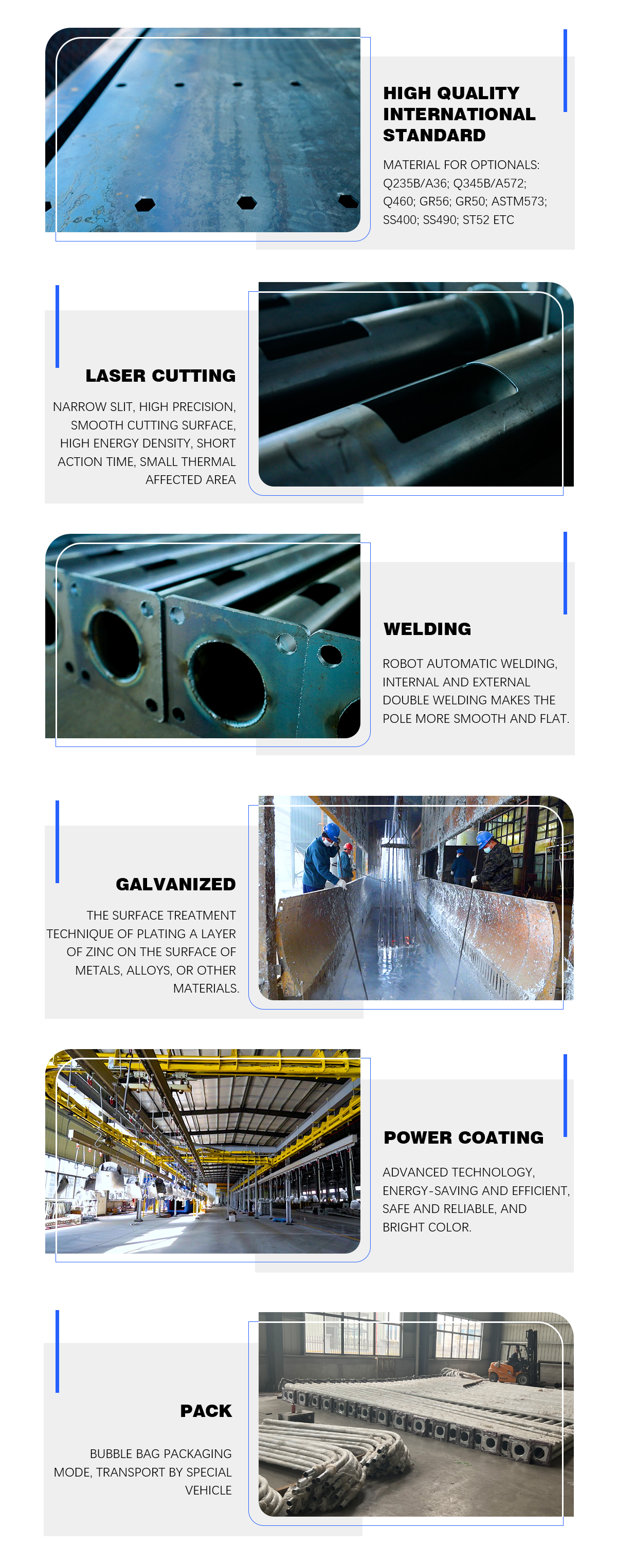

Material: Steel light poles can be made from carbon steel, alloy steel, or stainless steel. Carbon steel has excellent strength and toughness and can be chosen depending on the usage environment. Alloy steel is more durable than carbon steel and is better suited for high-load and extreme environmental requirements. Stainless steel light poles provide superior corrosion resistance and are best suited for coastal regions and humid environments.

Lifespan: The lifespan of a steel light pole depends on various factors, such as the quality of the materials, the manufacturing process, and the installation environment. High-quality steel light poles can last more than 30 years with regular maintenance, such as cleaning and painting.

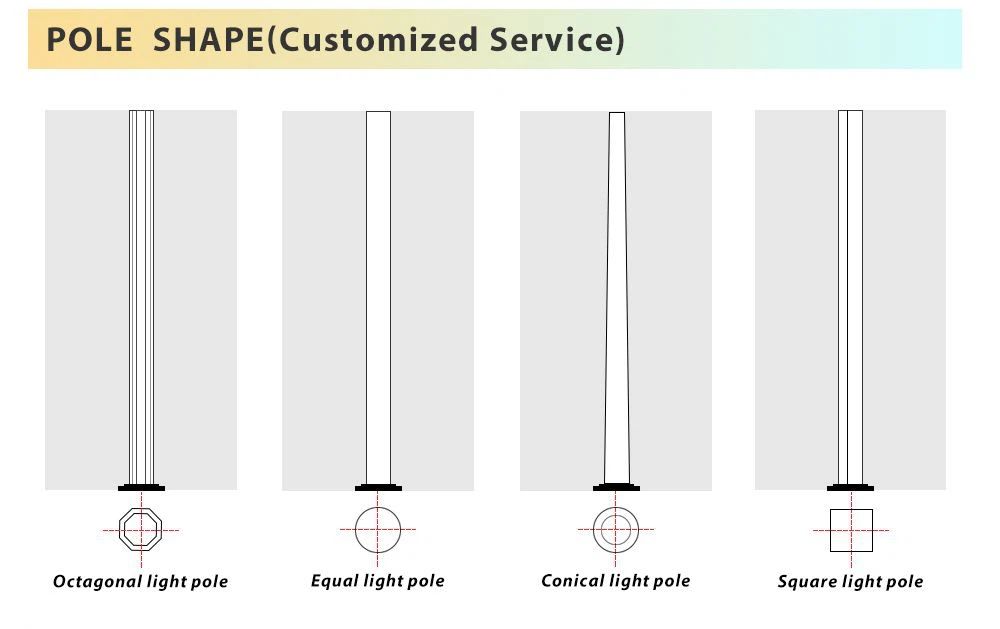

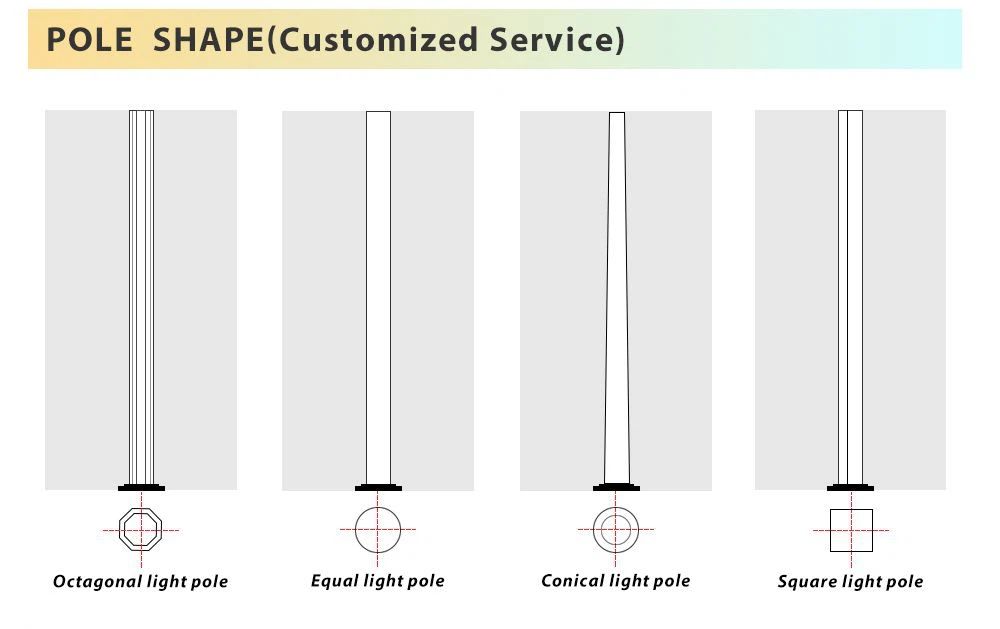

Shape: Steel light poles come in a variety of shapes and sizes, including round, octagonal, and dodecagonal. Different shapes can be utilized in various application scenarios. For instance, round poles are ideal for wide areas like main roads and plazas, while octagonal poles are more appropriate for smaller communities and neighborhoods.

Customization: Steel light poles can be customized according to the specific requirements of the client. This includes choosing the right materials, shapes, sizes, and surface treatments. Hot-dip galvanizing, spraying, and anodizing are some of the various surface treatment options available, which provide protection to the surface of the light pole.

In summary, steel light poles offer stable and durable support for outdoor facilities. The material, lifespan, shape, and customization options available make them an excellent choice for various applications. Clients can choose from a range of materials and customize the design to meet their specific requirements.