I-15M 20M 25M 30M 35M Isibani Esiphezulu Se-Solar Esiphakamisa Ngokuzenzakalelayo

Izidingo zendawo yokwakha

Indawo yokufaka isibani sensika ephakeme kufanele ibe yithafa futhi ibe banzi, futhi indawo yokwakha kufanele ibe nezindlela zokuvikela zokuphepha ezithembekile. Indawo yokufaka kufanele ihlukaniswe kahle ngaphakathi kwerediyasi yezinsika eziyi-1.5, futhi abasebenzi abangebona abokwakha abavunyelwe ukungena. Abasebenzi bokwakha kumele bathathe izinyathelo zokuvikela zokuphepha ezahlukahlukene ukuqinisekisa ukuphepha kwempilo yabasebenzi bokwakha kanye nokusetshenziswa okuphephile kwemishini namathuluzi okwakha.

Izinyathelo zokwakha

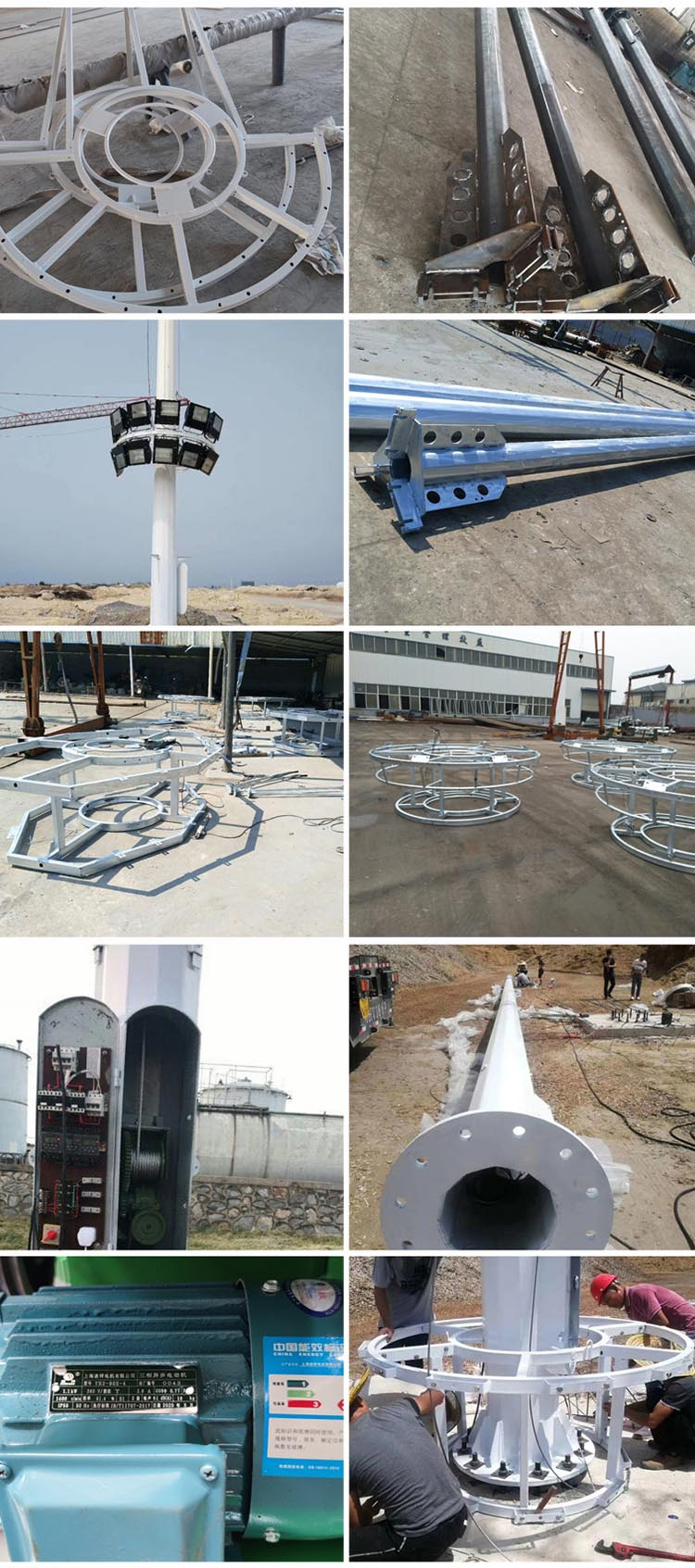

1. Uma usebenzisa isibani se-mast ephezulu esivela emotweni yokuthutha, beka i-flange yesibani se-pole ephezulu eduze kwesisekelo, bese uhlela izingxenye ngokulandelana kusukela kokukhulu kuya kokuncane (gwema ukuphathwa okungadingekile ngesikhathi sokuhlangana);

2. Lungisa induku yokukhanyisa yengxenye engezansi, faka intambo yentambo eyinhloko, phakamisa ingxenye yesibili yenduku yokukhanyisa nge-crane (noma i-tripod chain hoist) bese uyifaka engxenyeni engezansi, bese uyiqinisa nge-chain hoist ukuze wenze imiphetho ye-internode iqine, imiphetho namakhona aqondile. Qiniseka ukuthi uyifaka endandatho ye-hook ngendlela efanele (hlukanisa ingaphambili nengemuva) ngaphambi kokufaka ingxenye engcono kakhulu, futhi iphaneli yesibani esihlanganisiwe kumele ifakwe kusengaphambili ngaphambi kokufaka ingxenye yokugcina yenduku yokukhanyisa;

3. Ukuhlanganisa izingxenye ezisele:

a. Uhlelo lokudlulisa: luhlanganisa kakhulu i-hoist, intambo yensimbi, i-skateboard wheel bracket, i-pulley kanye nedivayisi yokuphepha; idivayisi yokuphepha iwukuqiniswa kwamaswishi okuhamba amathathu kanye nokuxhumeka kwemigqa yokulawula. Indawo yeswishi yokuhamba kumele ihlangabezane nezidingo. Kuwukuqinisekisa ukuthi iswishi yokuhamba iyisiqinisekiso esibalulekile sezenzo ezifika ngesikhathi nezinembile;

b. Idivayisi yokumiswa ngokuyinhloko iwukufakwa okufanele kwezingwegwe ezintathu kanye nendandatho yengwegwe. Uma ufaka ingwegwe, kufanele kube negebe elifanele phakathi kwensika yokukhanya kanye nensika yokukhanya ukuqinisekisa ukuthi ingasuswa kalula; indandatho yengwegwe kumele ixhunywe ngaphambi kokufakwa kwesigwegwe sokugcina.

c. Uhlelo lokuvikela, ikakhulukazi ukufakwa kwesivikelo semvula kanye nenduku yombani.

Ukuphakamisa

Ngemva kokuqinisekisa ukuthi isokhethi liqinile futhi zonke izingxenye zifakiwe njengoba kudingeka, ukuphakamisa kwenziwa. Ukuphepha kumele kutholakale ngesikhathi sokuphakamisa, indawo kufanele ivalwe, futhi abasebenzi kufanele bavikelwe kahle; ukusebenza kwe-crane kufanele kuhlolwe ngaphambi kokuphakamisa ukuqinisekisa ukuphepha nokuthembeka; umshayeli we-crane nabasebenzi kufanele babe neziqu ezifanele; qiniseka ukuthi uqinisekisa isibani esizophakanyiswa, Vimbela ikhanda lesokhethi ukuthi lingawi ngenxa yamandla lapho liphakanyiswa.

Iphaneli yesibani kanye nomhlangano kagesi womthombo wokukhanya

Ngemva kokumiswa kwesigxobo sokukhanyisa, faka ibhodi lesifunda bese uxhuma ugesi, ucingo lwemoto kanye nentambo yokushintsha ukuhamba (bheka umdwebo wesifunda), bese uhlanganisa iphaneli yesibani (uhlobo oluhlukanisiwe) esinyathelweni esilandelayo. Ngemva kokuba iphaneli yesibani seliqediwe, hlanganisa izinto zikagesi zomthombo wokukhanya ngokwezidingo zomklamo.

Ukulungisa amaphutha

Izinto eziyinhloko zokulungisa amaphutha: ukulungisa amaphutha ezinsika zokukhanya, izinsika zokukhanya kumele zibe nokuma okuqondile, futhi ukuphambuka okuvamile akufanele kudlule ingxenye eyodwa kwenkulungwane; ukulungisa amaphutha ohlelweni lokuphakamisa kufanele kufeze ukuphakamisa okubushelelezi nokukhulula; Isibani singasebenza ngokujwayelekile nangokuphumelelayo.

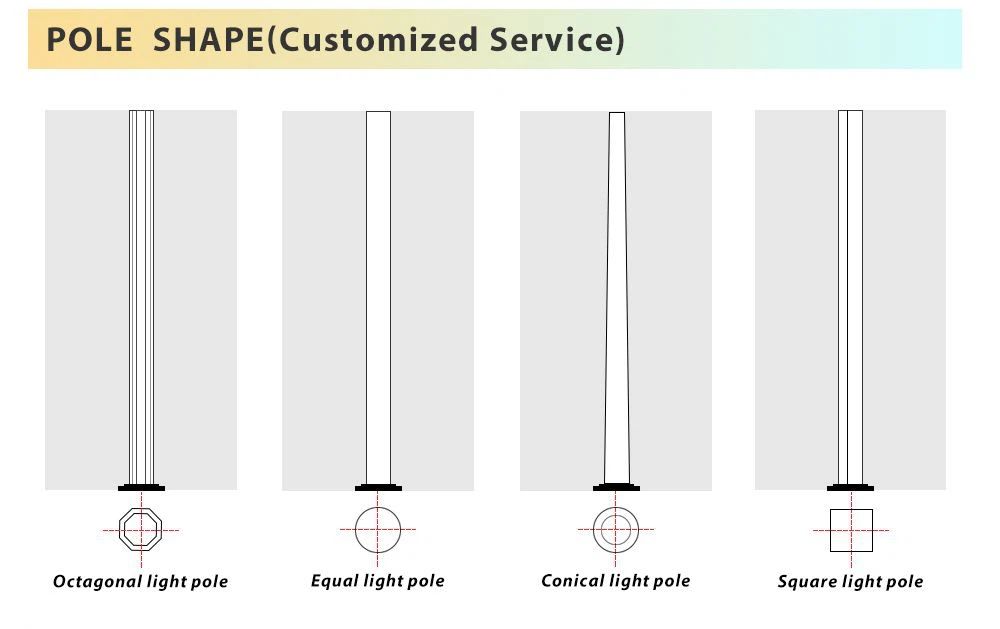

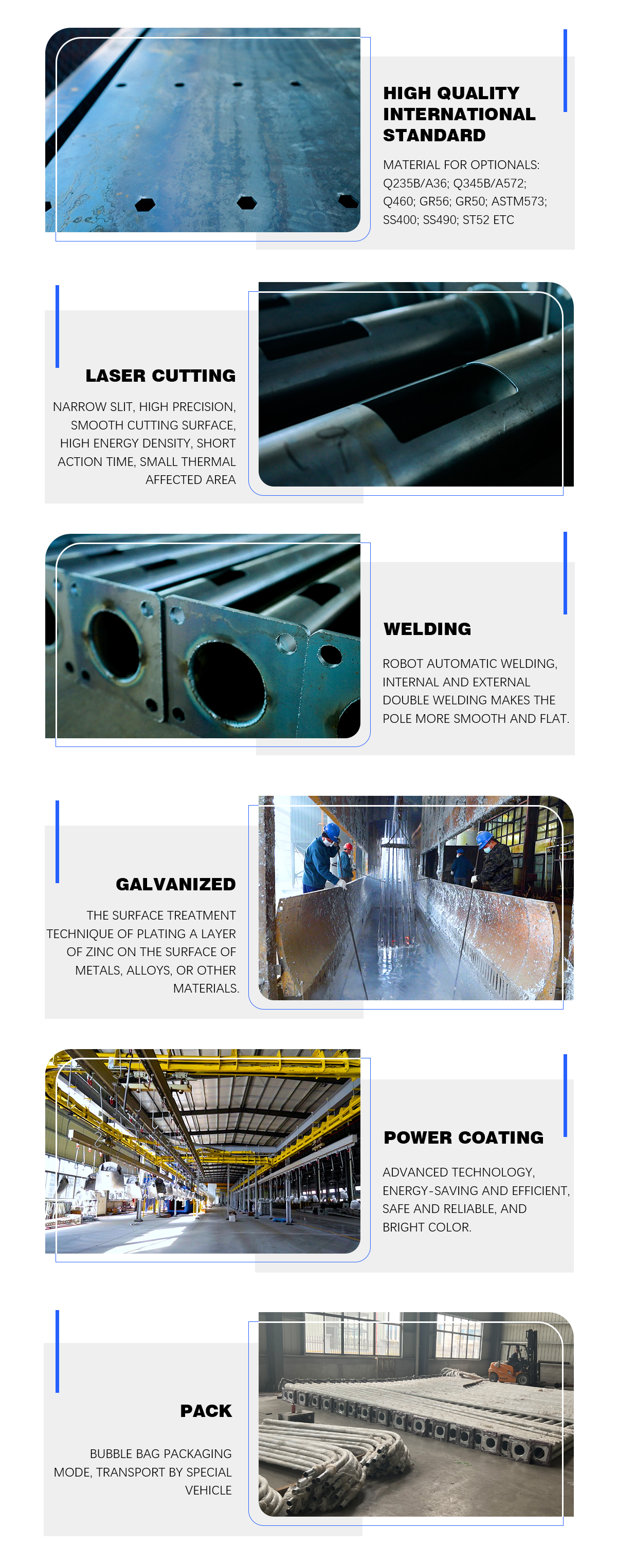

Isibani sokukhanya se-mast esiphezulu sibhekisela ohlotsheni olusha lwedivayisi yokukhanyisa eyakhiwe isibani sokukhanya esimise okwekholamu yensimbi esinokuphakama kwamamitha ayi-15 kanye nohlaka lokukhanya oluhlanganisiwe olunamandla aphezulu. Siqukethe izibani, izibani zangaphakathi, izinti kanye nezingxenye eziyisisekelo. Singakwazi ukuqedela uhlelo lokuphakamisa oluzenzakalelayo ngenjini yomnyango kagesi, ukulungiswa okulula. Izitayela zezibani zinganqunywa ngokuya ngezidingo zomsebenzisi, indawo ezungezile, kanye nezidingo zokukhanyisa. Izibani zangaphakathi zakhiwe kakhulu izibani zokukhanya kanye nezibani zokukhanya. Umthombo wokukhanya yizibani ze-LED noma ze-sodium ezicindezelwe kakhulu, ezinerediyasi yokukhanyisa yamamitha angama-80. Umzimba wesibani ngokuvamile uyisakhiwo somzimba owodwa sesibani sesibani se-polygonal, esigoqwa ngamapuleti ensimbi. Izinti zokukhanya zigoqwe ngokushisa futhi zimbozwe nge-powder, isikhathi sokuphila esingaphezu kweminyaka engama-20, zingabizi kakhulu nge-aluminium kanye nensimbi engagqwali.